How Resin 3D Printers Are Revolutionizing Jewelry Manufacturing | 3D MCast

Discover how 3D MCast helps jewelers transform traditional investment casting with resin 3D printers. Learn how 3D printing enables faster production, easier customization, and intricate jewelry designs.

Introduction

Modern jewelers are embracing resin 3D printers to redefine the traditional investment casting process. With the help of advanced digital tools, jewelers can now produce detailed resin patterns, shorten production time, and explore design possibilities that were once out of reach.

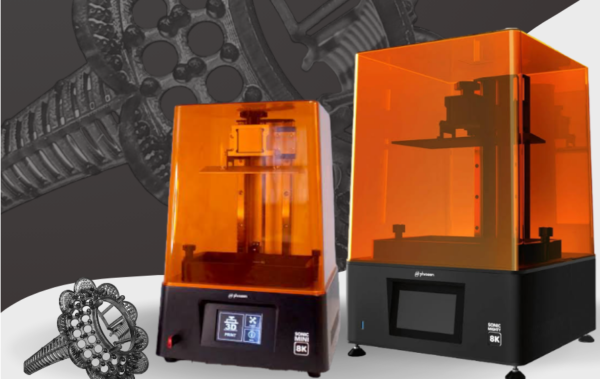

At 3D MCast, we specialize in providing high-precision 3D printing solutions for jewelry manufacturing, enabling designers and manufacturers to turn their creative visions into reality faster and more efficiently.

The Challenges Jewelers Face

Jewelry making is a craft that demands precision and creativity — but traditional techniques come with several challenges:

- Customers expect exclusive, high-quality designs.

- Traditional craftsmanship is time-consuming and requires years of skill.

- Any design modification demands a new investment pattern.

For generations, handcrafting and lost-wax casting have been the foundation of jewelry production. While these methods produce beautiful results, they are labor-intensive and costly when errors occur.

The Digital Transformation in Jewelry Manufacturing

Today, digital design and resin 3D printing are transforming how jewelry is made. By combining CAD design software with high-resolution resin 3D printers, jewelers can create highly detailed wax-like models ready for casting — reducing cost, minimizing human error, and improving turnaround time.

At 3D MCast, our resin 3D printing solutions seamlessly integrate with traditional casting workflows, offering jewelers a perfect balance between artistry and technology.

Key Benefits of Resin 3D Printing for Jewelers

1. Faster Production

Traditional jewelry making requires hand-carving wax patterns, creating molds, and casting metals like gold or silver — each step taking significant time and effort.

Using resin 3D printers from 3D MCast, jewelers can design their pieces digitally in CAD software, then print the pattern directly in castable resin. This eliminates manual carving and dramatically shortens the overall production process.

2. Effortless Personalization

With 3D printing, jewelers can easily offer custom designs without committing to large production runs. There’s no minimum order quantity — just pure creative freedom.

3. Limitless Design Freedom

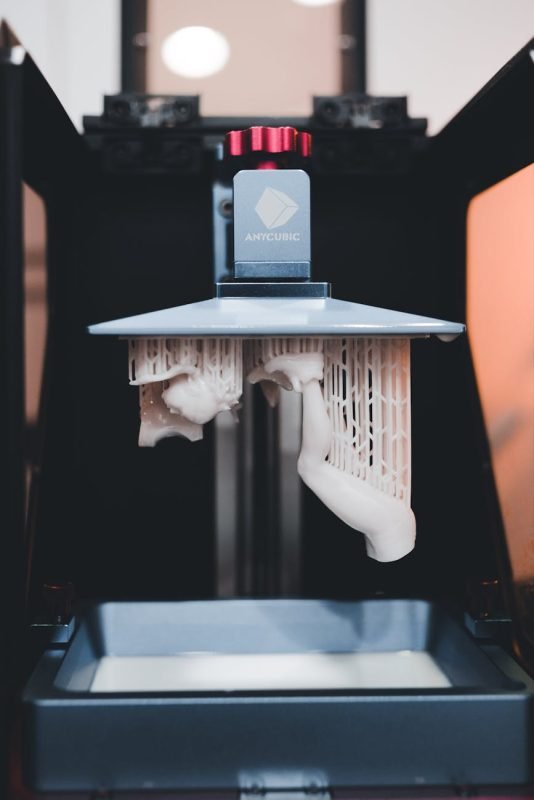

Traditional jewelry making has physical limits — but 3D printing breaks them all. Jewelers can now design complex patterns, intricate lattice structures, and hollow pieces that are nearly impossible to handcraft.

With 3D MCast’s high-precision resin printers, you can print detailed jewelry models using castable resins.

4. Lightweight and Durable Designs

One of the major advantages of 3D printing is control over density and weight. Designers can choose a 100% solid infill for strength or reduce it to 80% (or lower) for lightweight pieces.

This allows for innovative, durable, and comfortable jewelry designs while optimizing material use and production costs.

Workflow: Jewelry Making with Resin 3D Printers

At 3D MCast, we make it simple for jewelers to integrate resin 3D printers into their production workflow. The process involves four key steps:

Step 1: Prototyping

Design iterations are 3D printed with standard resin to check shape, detail, and design accuracy.

Step 2: Fitting

The printed models are used for customer fittings and feedback before final approval.

Step 3: Investment Pattern

The approved design is 3D printed in castable resin, creating a flawless investment pattern ready for casting.

Step 4: Casting

The resin pattern is used to form a mold, and molten metal — gold, silver, or another material — is poured to produce the final piece.

Conclusion

Resin 3D printing has become a game-changer for the jewelry industry, combining traditional craftsmanship with cutting-edge technology. It empowers jewelers to work faster, create intricate designs, and offer customers unmatched customization.

At 3D MCast, we help jewelry professionals embrace this transformation with precision resin 3D printers designed for speed, accuracy, and exceptional surface quality. Whether you’re a designer, caster, or manufacturer — 3D printing is your next step toward innovation.