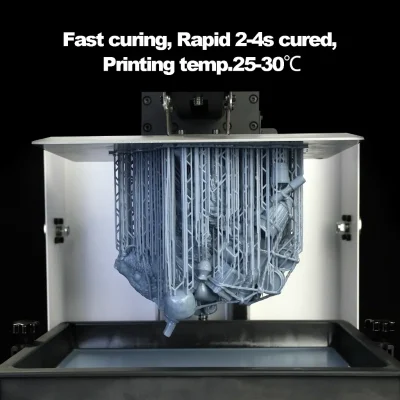

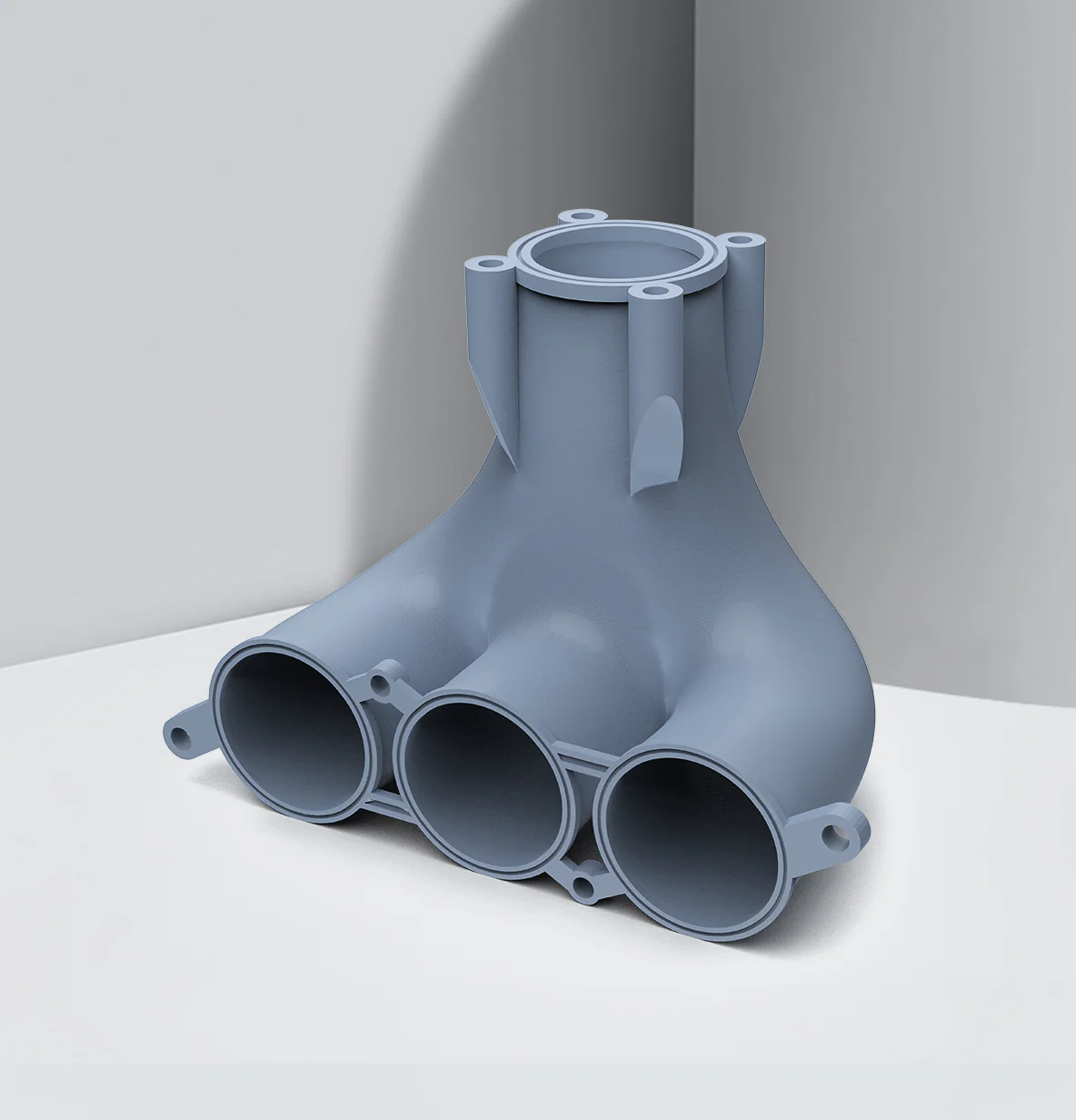

Anycubic Tough Resin 2.0

Product Features

● Exceptional Toughness & Resistant to Breakage

● Strong Elongation & High Flexibility

● High Precision, Minimal Shrinkage

₨ 12,000

Share:

Product Description

Instructions for Use

(1) Before use:

Shake the liquid resin before use;

Clean the resin tank and the molding platform to keep the bottom of the resin tank in light

transmission.

(2) When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements;

Select the correct print parameters and settings for printing.

(3) After use:

After printing, please use the matching tools for post-processing, including blade, diagonal

pliers,tweezers,containers,gloves;

ethanol(≥95%),lactate or isopropyl alcohol cleaning solution;

(4) Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken

out and drained; ANYCUBlC Wash and Cure machines are suggested to ensure better effect.

C.Proper processing, such as removing support, polishing, coloring, etc.

Precautions

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light

to avoid high temperature or sunlight. - Suggested operating temperature is 18-35’c, and a low temperature may affect the printing effect, thus, the

resin can be properly preheated before use (not more than 60°C). - If the resin pigment settles, it can be used after stirring or shaking.

- In order to ensure the performance of the resin, please take out the model in time after cleaning to avoid the model soaking in water for a long time.

- To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the

light source after curing.Therefore, the following steps are recommended:

(1) The intensity of mercury lamp or LeD light source is 5-10mW/m?, and the duration is no more than 1 hour (self-regulation);

(2)The exposure time in the sun (summer) is around 1 hour;

(3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury

lamps is prohibited.

(4) lt is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive

material.